Vacuum forming

When starting up this process the raw material is always a flat sheet of plastic which can vary in size, thickness, color and surface structure. Our vacuum forming machines automatically insert a sheet into the frame. Hereafter, the sheet is heated up. When the material has reached the needed temperature for processing the sheet will be blown up in a bubble. A mold moves up into the sheet and small holes in the mold ensure by vacuum that the plastic adheres to the mold.

This is how an item is formed. Next, the sheet is being cooled by air and a water-cooling system in the mold. When the cooling process is over the item is removed from the vacuum forming machine by robots and the process starts over.

After being vacuum formed, the item is typically processed. How this happens depends on which process we have agreed with the customer. Often, the item is processed in a CNC machine where excess plastic is cut away and holes milled out for various purposes. Next, we can do assembly work if needed. Examples of this are installation of pop rivets, screws, washers, handles or the like. Requirements for this part may vary and always a customized solution.

Vacuum forming is typically the right manufacturing method when needing relatively large items in smaller or medium sized series. Examples of vacuum formed items are covers and other protective solutions such as doors, hatches, interior parts and different types of trays.

Gibo has a large scale of different vacuum forming machines including automated production lines. This enables us to produce multiple technical plastic items with minimal lead time. Based on drawings, requirements and yearly demand we can advise on whether vacuum forming is the ideal manufacturing method for you.

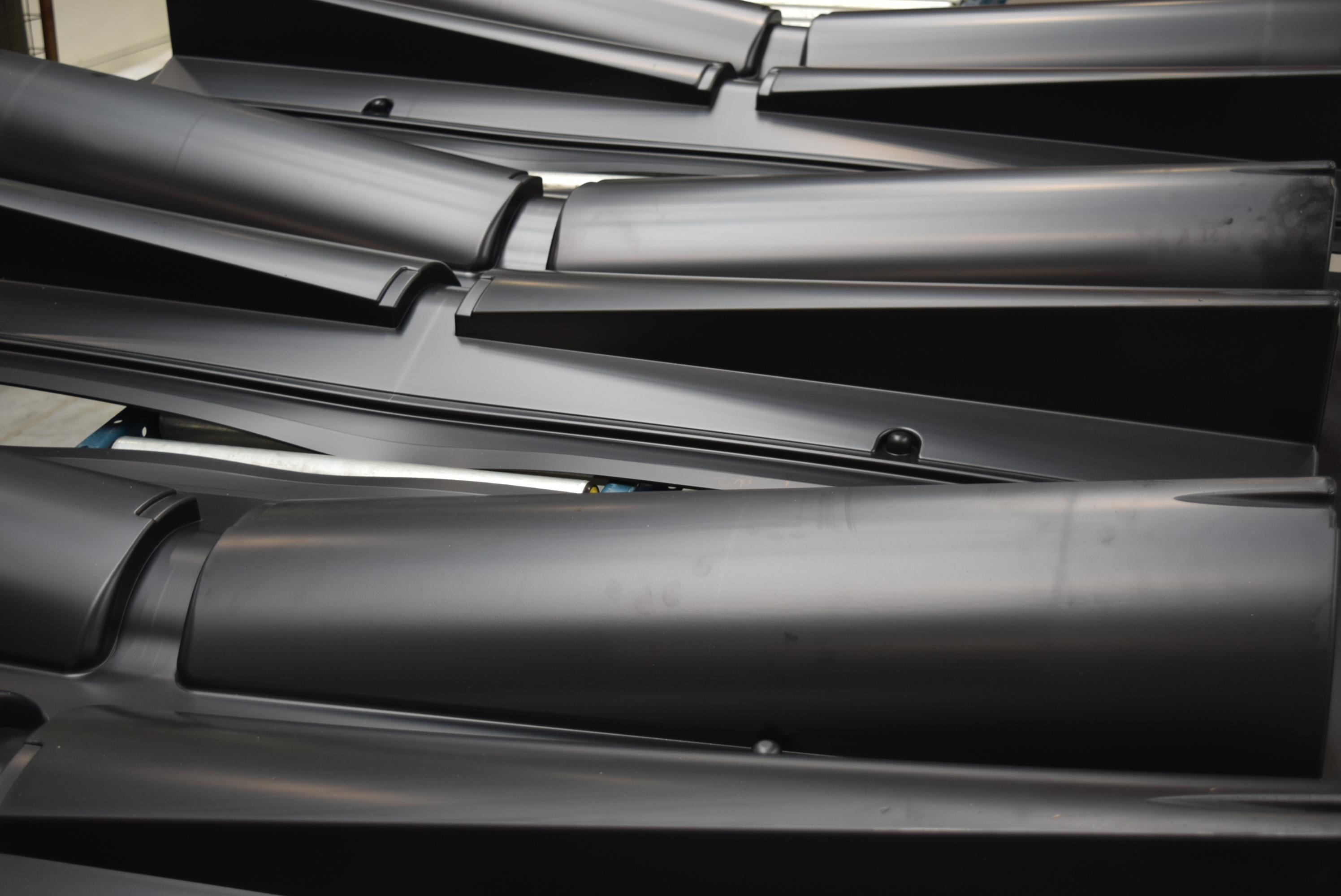

Here you can see vacuum formed parts cooling down before they proceed to a CNC-machine.

The robot has just placed a new sheet which is ready for heating and is about to transfer the vacuum formed part to the milling process.